Low carbon footprint and high strength: why choose our bainitic steels

Today, manufacturers are increasingly concerned about reducing the carbon footprint of their products. Our customers are no exception, and it is with this in mind that ArcelorMittal Long Products Canada is working hard to develop steel grades that maintain the inherent benefits of steel while offering a better environmental record.

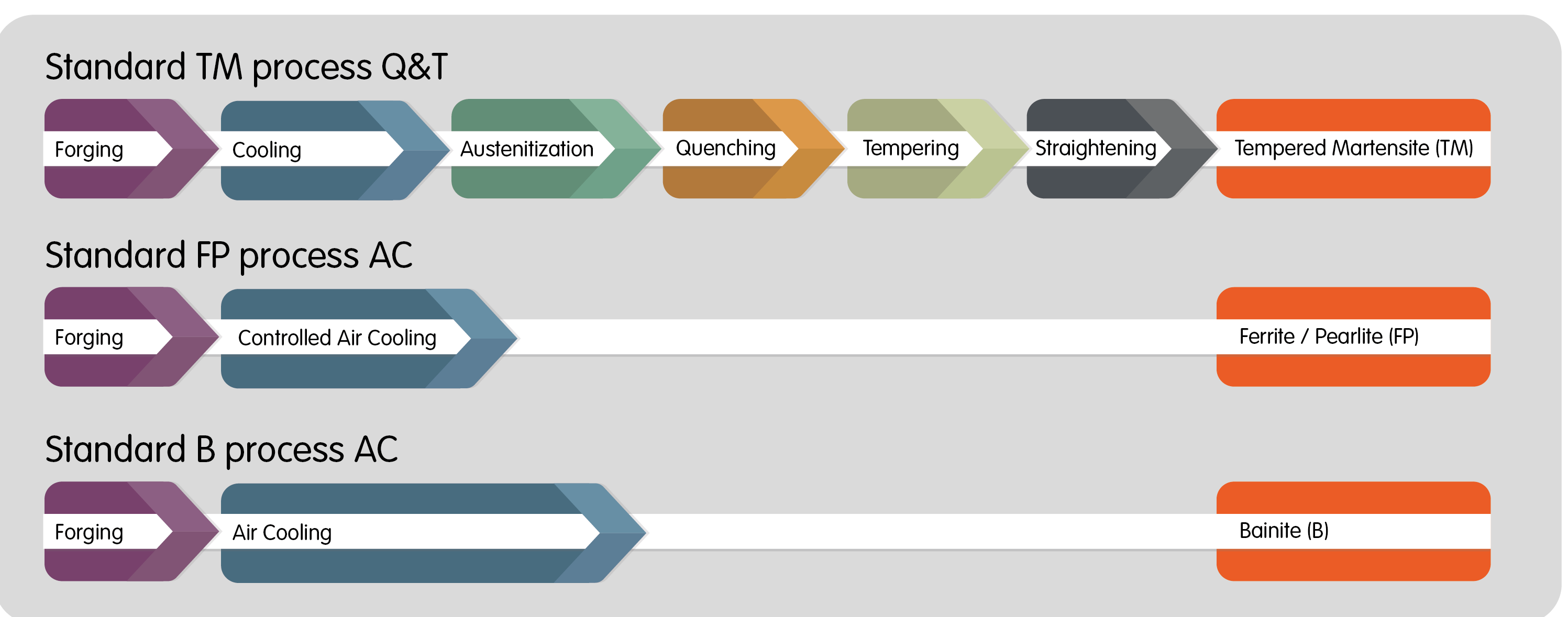

Our SOLAM® B – Bainite hot forging steels offer high mechanical properties after hot forging without the usual heat treatments like quenching and tempering. It is therefore a more environmentally friendly solution that reduces the carbon emissions generated by its production.

SOLAM® B offers the following features:

- Wide range of diameters (20 mm – 0.8″<Deq<100 mm – 3.9″)

- No heat treatment (only air cooling after hot forging)

- High mechanical characteristics: UTS > 1100 MPa (160 ksi)

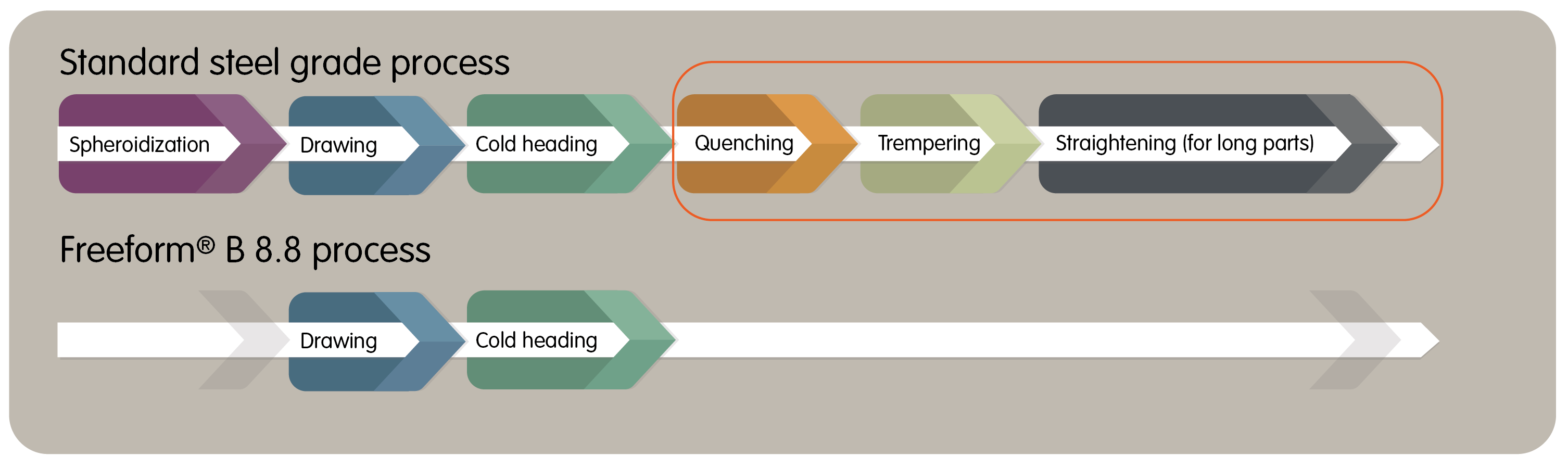

The Freeform® B family allows the production of cold heading parts that will meet the mechanical properties of classes 8.8 and 10.9 in the deformation range usually expected by customers (15% to 45%). These grades are characterized by the absence of heat treatment in the intermediate and final phases. This makes the Freeform® B a family of steels with a lower carbon footprint and a wise environmental choice.

“ArcelorMittal Long Products Canada’s steel already features one of the lowest carbon footprints on the planet due to our process and the use of renewable hydroelectricity. With SOLAM® B – Bainite and Freeform® B, we are going even further to bring to market an innovative steel that will meet the challenges of our current and future customers,” says Philippe Boulanger, Chief Marketing Officer of ArcelorMittal Long Products Canada.

Want to know more about bainitic steels? We invite you to view one of our three webinars presented by ArcelorMittal’s global Research and Development Center – Bars and Wires in Maizières-les-Metz (France).

- Our Bars & Wires laboratory, by François-Xavier Hoche (R&D Program Coordinator, ArcelorMittal)

- Bainitic and TRIP grades for hot and cold forging, by Caroline Persem (Global R&D ArcelorMittal)

- Freeform® grades, by Marion Frotey (Global R&D ArcelorMittal)

To access these webinars, please send us an e-mail at isiwebinaire@arcelormittal.com; a link to view them will then be sent to you.

Would you like to speak to one of our sales representatives to discuss our bainitic steels or our other steel products in more detail? Contact us at marketing-long-canada@arcelormittal.com