Wire rod

Our rod mills manufactures wire rod with our steel. This rod is then sold in four main business segments:

- Low carbon which is mainly catering to the construction industry for mesh product and nails;

- Cold heading which is made of fasteners for the automotive industry and others;

- Welding consumable which is used almost everywhere, from the farmer welding his tractor to a robot welding a precise automotive part on an assembly line;

- Rebar in coil, mainly used for the construction industry.

Our rod products are manufactured to meet to the most demanding applications in the industry, and are clearly recognized for their high quality and reliability that has been proven over time. One of our main strengths is the solid relationship between our rod mill and steel plants, with the main goal always being to make world-class steel for our customers.

*Except where specified.

*Except where specified.

*Available in coarse or fine grain practice. Custom grades also available, please inquire.

Cold Heading Quality Rod

CHQ Rod is a quality designation, referring to rod suitable for making cold headed fasteners – screws, bolts, rivets, etc. of various shapes and sizes made from numerous steel grades. Wire rods for cold heading are tightly controlled for optimal chemical, metallurgical, and mechanical characteristics providing maximum ductility for cold forming, while ensuring the required final heat treat response.

ArcelorMittal Long Products Canada supplies CHQ rod to our customers producing engineered fasteners for automotive, general manufacturing and construction applications. We are able to produce very low residual steel and tailor it to customer chemical specification with our steel making practice that incorporates high Directly Reduced Iron (DRI) content, which is a very pure source of iron, and controlled alloy additions.

Welding Quality Rod

In many welding applications, a filler material is required, which is usually a specially controlled drawn wire that is made from welding quality rod. To make a sound weld, the chemistry of the filler metal is very important because it must fuse with the surrounding parent metal being joined, and after solidification have mechanical properties compatible with the parent metal.

ArcelorMittal Long Products Canada supplies numerous different grades of welding quality rod, each of them developed for specific customers with different chemistry ranges. The rod has carefully controlled chemistry and mechanical properties so that it can be drawn into wire for producing stick electrodes, and spools of wire for continuous wire feed applications of either solid welding wire or flux-cored welding wire.

ArcelorMittal Long Products Canada has facilities uniquely positioned to produce the best quality welding rod. Key to the process is our ability to use up to 100% DRI as the feedstock – a very pure source of iron, that allows us to produce very low residual steel and tailor it to almost any desired alloy.

High Carbon Quality Rod

Rod is considered high carbon if it has over 0.5% carbon. The carbon imparts strength, yet still permits good drawability into wire. The HCQ rod can be drawn and heat treated to obtain final mechanical properties. Common applications include springs, music wire and stranded cables.

The production of this rod requires special practices at continuous casting to avoid centreline segregation in the cast billets. ArcelorMittal Long Products Canada is well equipped for this task with electromagnetic stirring (EMS) and billet cooling practices specially designed for high carbon steel. Controlled cooling of the rod is also important to produce a consistent, fine pearlitic structure ideal for drawing.

Custom grades also available, please inquire.

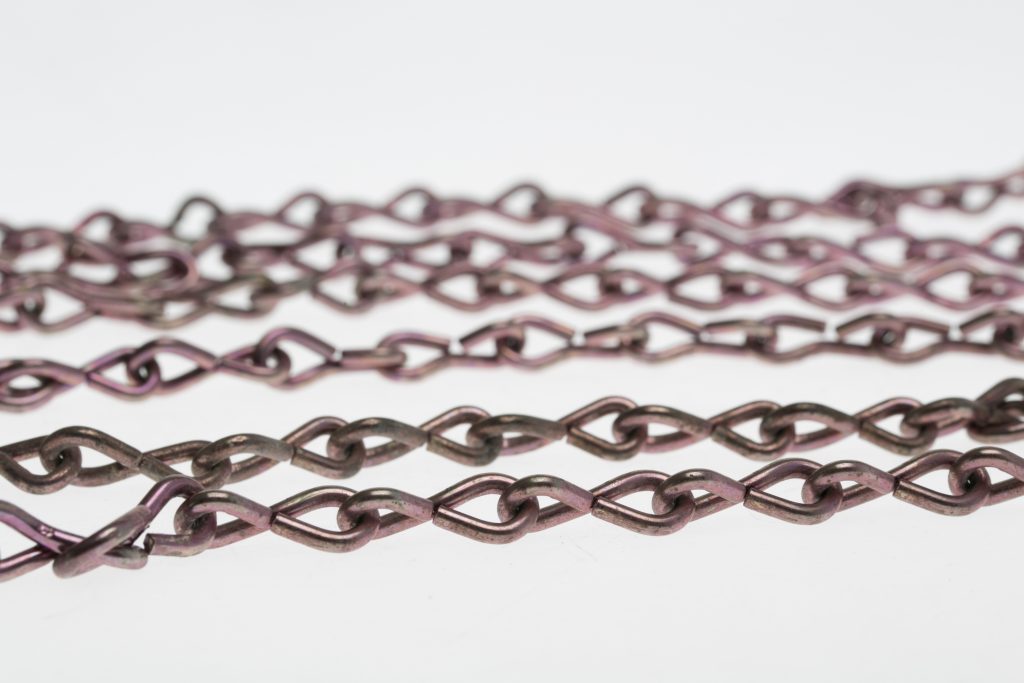

Industrial Quality Wire Rod

IQ Rod is a quality designation, referring to rod suitable for cold drawn parts with non-critical applications such as nails, mesh, fencing, chains, paper clips, staples, bailing wire, dishwasher and freezer racks, supermarket carriers, animal cages, etc. of various shapes and sizes made from numerous steel grades. This IQ rod, when cold drawn, is suitable for galvanizing or chrome plating for corrosion protection.

ArcelorMittal Long Products Canada supplies IQ rod to our customers producing parts for automotive, appliance, agriculture, construction applications.

Key Properties

Cold Heading Quality Rod

- Chemistry control

- Cold ductility

- Dimensional control

- Surface quality

- Microstructure homogeneity

Welding Quality Rod

- Chemistry control

- High Ductility

High Carbon Quality Rod

- Microstructure homogeneity

- Steel cleanliness

- Tensile strength

- Good drawability (ductility)

- Surface quality

Industrial Quality Wire Rod

- Chemistry control

- Microstructure homogeneity

- Descaling ability